Good ol’ days..

Twenty years ago, when I had my first windshield replaced by an auto glass company, a guy came out in a little Ford Ranger pick-up truck with a new windshield. He removed the old, cracked glass, glued a new one in, moved my rear view mirror over to the new glass and he was done. Took him thirty minutes, as best. The glass was meant to keep the rain and bugs out of my face and it worked.

As automotive technology has evolved, every part of the vehicle has also evolved, including the glass and technology that is dependent on that glass. Much of that technology is safety related, making it ever more important that Auto Glass Companies also learn and evolve with that technology.

Fast forward twenty years…

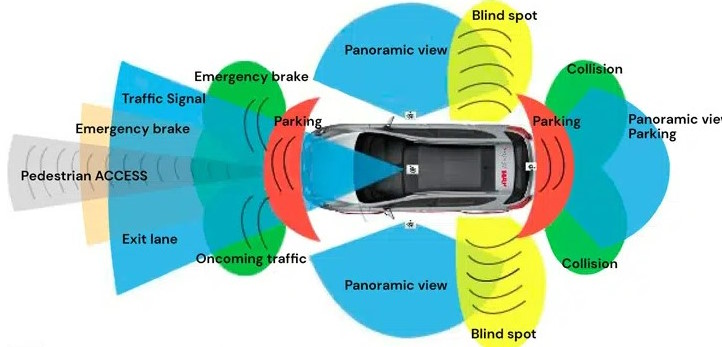

In the example of replacing a cracked windshield, the replacement of the glass is just one small step in the process now. Before they even put a single tool to the vehicle, a Technician must now check the functionality of existing vehicle safety systems that are dependent on the windshield to function properly. It’s important to know what is and isn’t working, prior to the glass replacement. Then, they disassemble various components attached or in some way dependent on the glass. That may include multiple cameras, sensors, wiring harnesses and other critical components. They replace the windshield and begin putting everything back in its proper and precise position. Any camera or sensor that is moved from its original, factory position is going to require calibration so that the vehicle’s computer is accurately assessing what the cameras and sensors are telling it. The calibration requires the use of hi-tech equipment that links to the vehicle’s onboard computer and initiates the process, sort of like reprogramming a computer. Once the calibration tool and vehicle computer have finished re-setting everything back to factory specifications, you simply can’t trust what the computer says is “good” without verifying out on the road. The Technician needs to test drive it, following manufacturer requirements, making sure that all related safety systems are performing as they should be.

With all the safety system considerations, that thirty minute windshield replacement of twenty years ago has evolved into a 2 or 3 hour process. That’s okay though, right? Hey, if it takes a little extra time to make sure my collision-avoidance system in my car keeps me from crashing into a pedestrian when the sun is in my eyes or my lane departure warning system keeps me from inadvertently sideswiping a mom and her three kids when I glance down at the radio, I’m okay with that. I mean, if my mechanic told me my brake job would take extra time to make sure my brakes work properly, I’m probably going to let him take whatever time he needs to get my brakes working properly. This is no different.

How does this affect me?

The main takeaway from all of this is that windshield replacement has become way more complex and many of those smaller shops and individuals who used to be able to swap out windshields in thirty minutes are being left behind by the demands of the technology. Most small shops just don’t have the resources or desire to invest the tens of thousands of dollars for the expensive systems required to interface with the vehicle computers. It’s also a long process for Technicians to be fully trained and certified so that every vehicle is given back to its owner, functioning just as it did when it was fresh from the factory with all safety systems working properly.

If you select an auto glass replacement company that isn’t equipped to calibrate and verify the hi-tech safety systems, they’re giving you back a vehicle that’s not safe or truly “complete”. Many States are pushing for legislation to require that these safety systems be properly calibrated, to keep unscrupulous companies from taking advantage of unsuspecting vehicle owners, putting them and the public at great risk.

Know the risks and choose your auto glass company wisely.